- Platform

Features

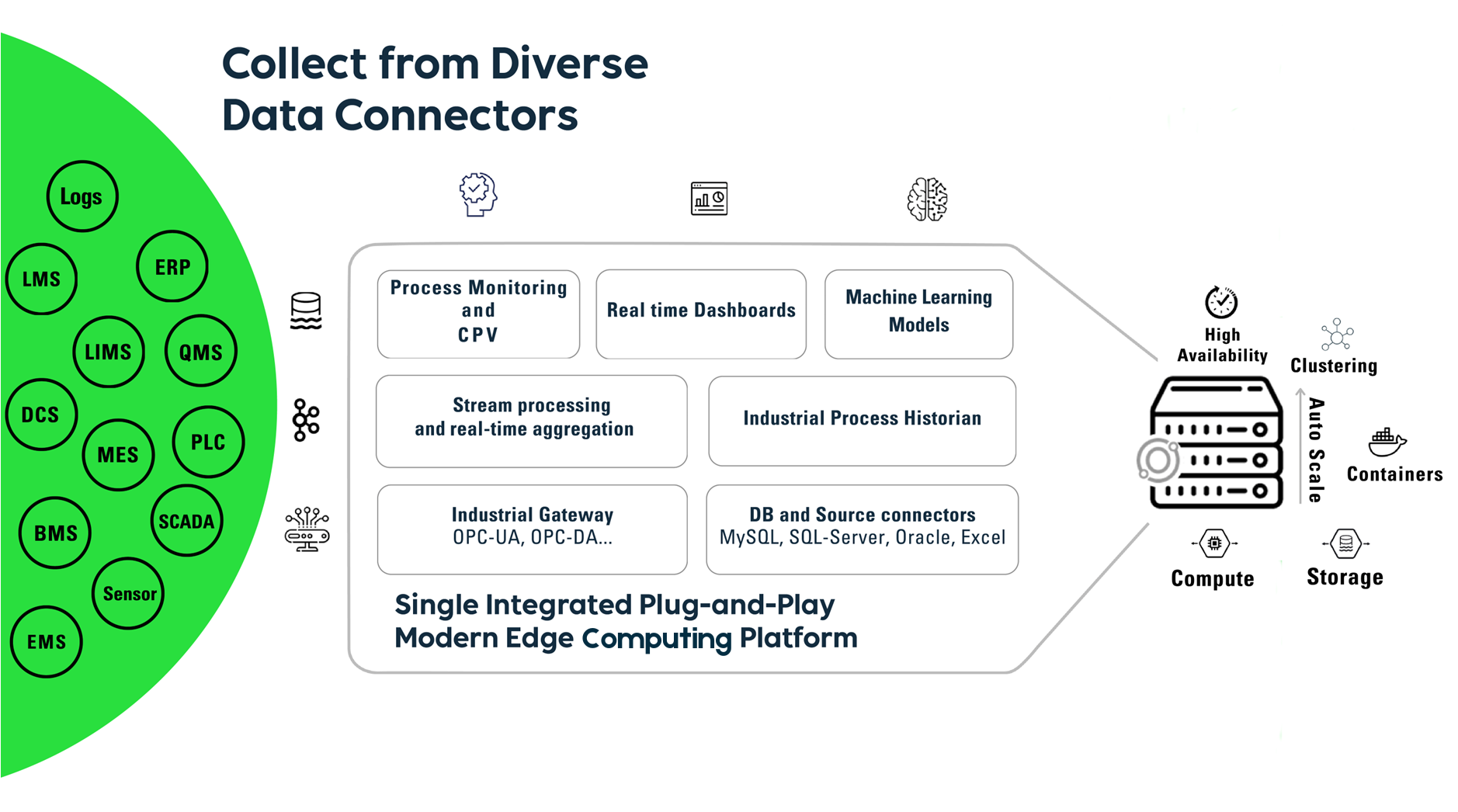

- Industrial Gateway Connect process machines and databases

- Real-time Alerting and Data Hub Alerts on any streaming message from data sources. Add contextual hierarchy and stream data as messages or triggers to external applications

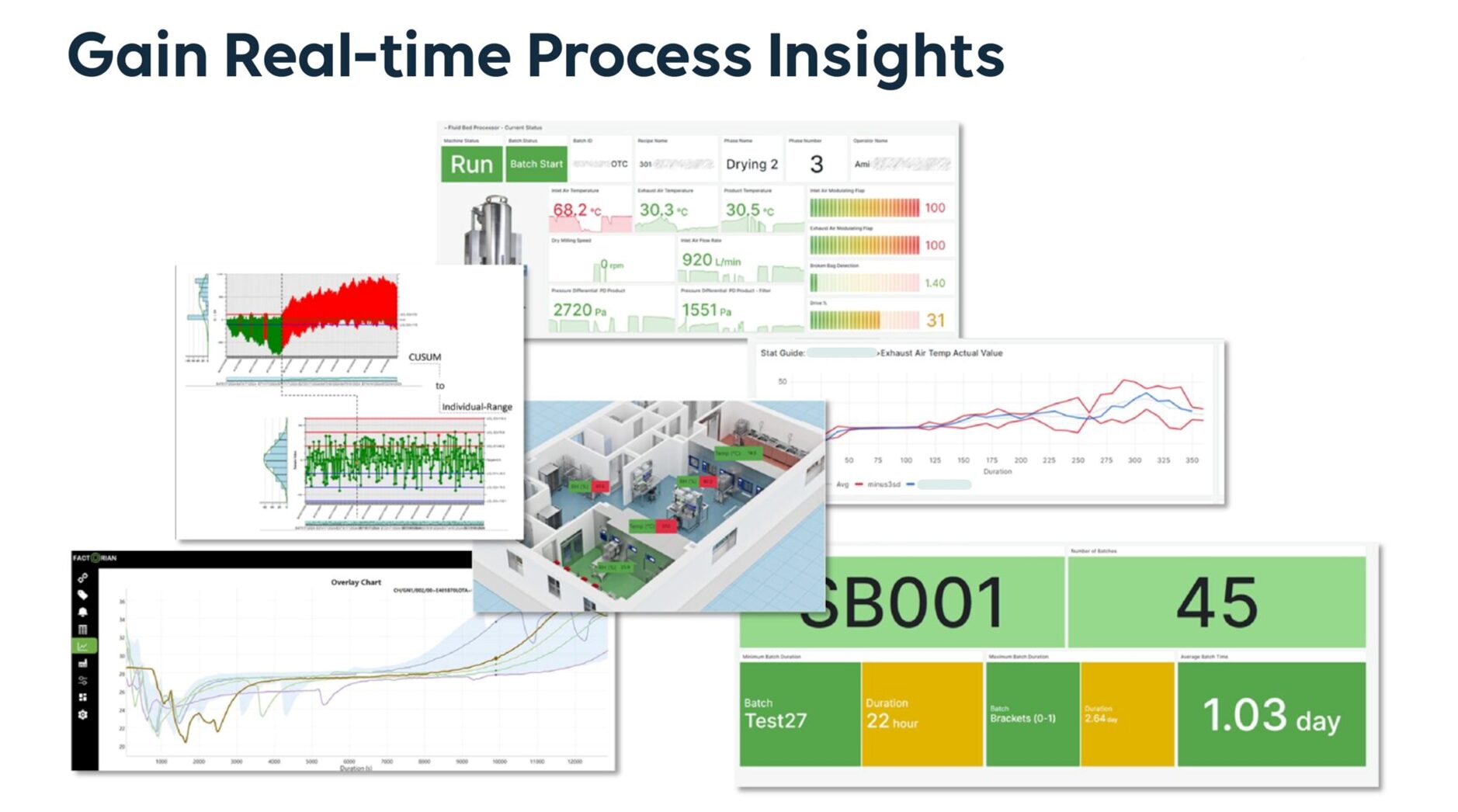

- Process Historian and Low-Code Data Platform A full-featured modern process data historian. Aggregate data to back up to cloud end-point (e.g., AWS, AZURE) or run Python code locally for machine learning

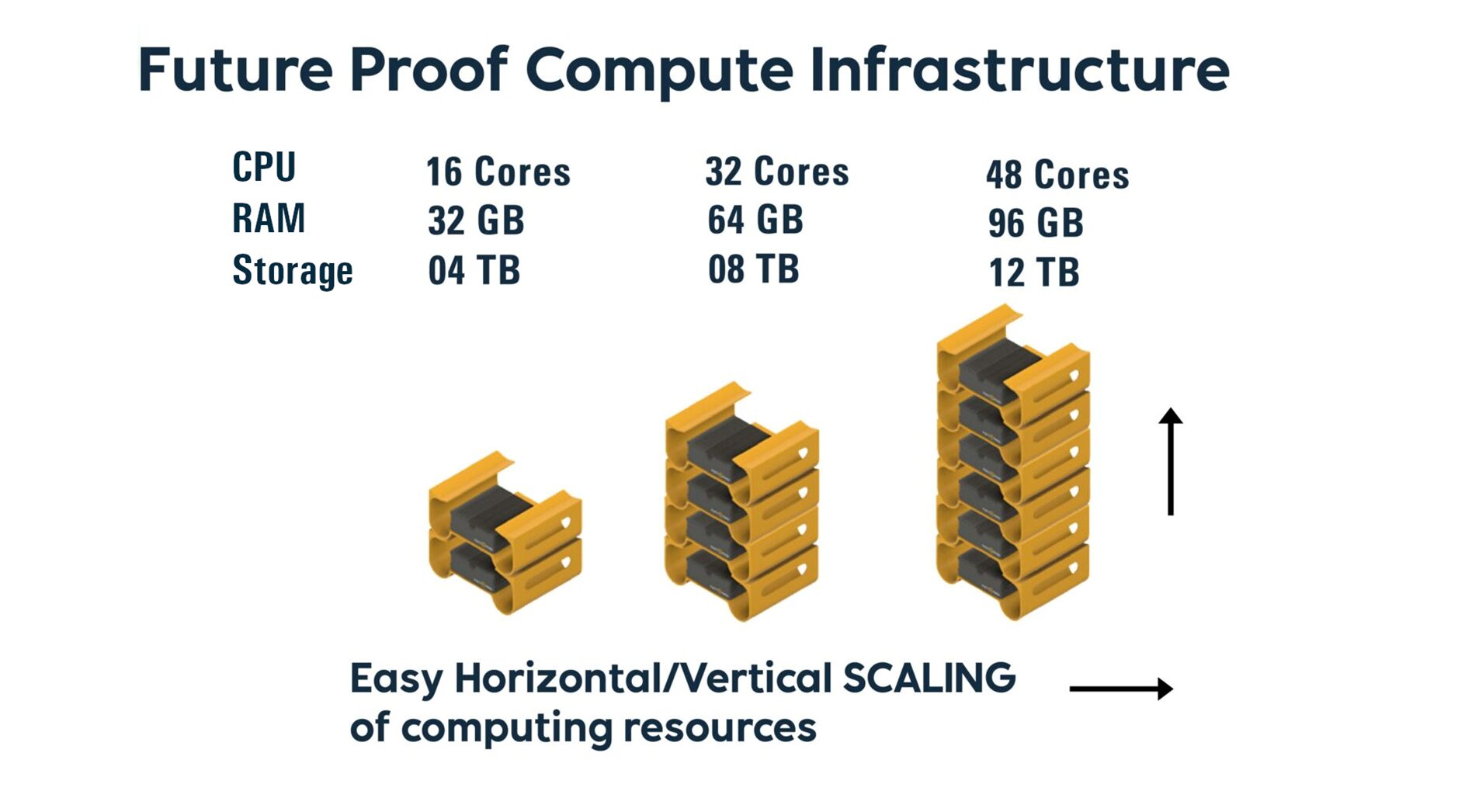

- Managed Hardware Provision additional vCPU, RAM or Storage by simply connecting plug-and-play Hyperconverged nodes

- Resources

- Contact Us

- Partners

- Support