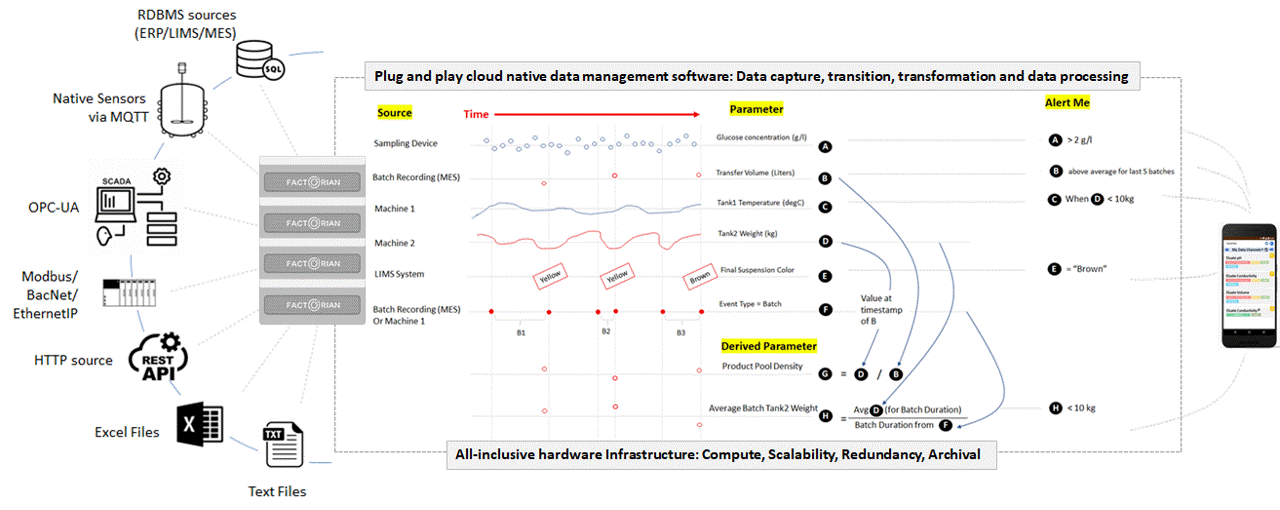

Following up on our earlier article titled “Edgy Cloud: Best of both worlds for batch manufacturing informatics” where we presented a high-level overview how computing is evolving and why computing on-premise at the edge make sense for many manufacturing domains, here in this article we present a little more granular detail on how we envision Factorian’s role in reducing real-time data processing challenges faced by batch manufacturing industries like pharmaceuticals, biotech, and specialty chemicals.

Most of us in process engineering or involved in manufacturing production spend our lives streamlining the process adverse “events” to “effective action” for continued process improvements and supply-chain robustness. This journey from detecting the event from a sensor (via a machine or manual observation/record) to making sense for effective action is not smooth and, we have to go through a convoluted path that involves an interdisciplinary journey needing understanding of

- Sensor electronics and chemistry

- Instrumentation protocols converting the electronics/chemistry to digital signals

- Conversion of these digital signals to digital data under a series of different transmission protocols (Modbus, Profinet, Ethernet IP, MQTT, OPC etc.)

- Temporary and long-term storage and historization of the digital process data

- Storing process context of digital data in a separate digital or manual repository (MES, Batch records, Logs etc.)

- Human (manual) judgement and subjectiveness (if a manual observation) involved in capturing process context

- Mixing the contextual data with streaming digital events data

- Re-archiving and re-storage of the mixed enriched contextual data to a source repository

- Retrieval of this contextual data from each source repository

- Combining and arranging this contextual data in a spread sheeting software

- Slicing and dicing of contextual data

- Deriving insights and metrics from contextual data

- Setting alerts on the metrics derived from contextual data

- Doing proactive monitoring to observe the event from re-occurring for prevention or timely resolution of event.

As indicated in these items above, the journey from impulse-to-impact is not straightforward. Not to forget, these steps didn’t even consider the computing infrastructure needs like:

- Server Hardware (processor),

- RAM memory

- CPU needs

- Hard disk space

- Scaling and clustering needs

- Redundancy and resiliency requirements

- Security and accessibility need etc.

When you combine these two long lists, this becomes a complex networked problem of people and departments involved in various interdisciplinary domains and accountability that never results in amicable and seamless, proactive, and timely outcomes for process optimizations that we seek.

Factorian is our attempt to resolve the data transversal challenges compounded with instrumentation, protocols, and infrastructure bottlenecks via our plug-and-play device that is scalable, no-code, protocol agnostic, edge friendly and built ground up for the manufacturing. We believe that this will not only solve the challenges faced by process engineers related to data accessibility but will also relieve the end user from the burden of provisioning and maintaining infrastructure. We aim to deliver the device as truly end-to-end solution for all the process awareness and process insights needs.